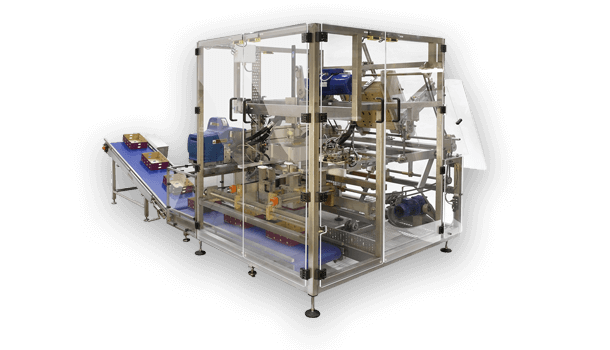

Packaging equipment is designed to pack large quantities of goods by using automated packaging methods. They can include vacuum packaging machines, filling machines, sealing machines, labeling machines, box forming machines, etc. These equipments can be utilized to increase speed and efficiency, reduce labor costs, improve packaging quality, and cut costs. These systems can be expensive to purchase and maintain. They also require technical expertise to function correctly.

These Are The Basic Principles That Guide The Design Of Packaging Equipment:

Protection- Packaging equipment should protect the product from damage, contamination, and deterioration during storage, transportation, and distribution.Containment- Packaging equipment should contain the product in a secure and stable manner, preventing spillage, leakage, and waste.

Convenience. The equipment used for packaging should be user-friendly, making it simple to use and also make it easily accessible.

Efficient Processing- It is important to create packaging equipment designed to maximize efficiency. This will reduce production costs, reduce waste and increase the quality of product.

Cost-effectiveness- Equipment for packaging should be able to provide the optimal balance between cost and performance and value for the user while being economically viable.

Usability- The packaging equipment should be simple to use, maintain, and tidy. This ensures that workers are secure and able to do their work in a safe manner.

Sustainable- Packaging equipment should minimize the use of materials to reduce waste and reduce environmental impacts.

These fundamentals can help ensure that the packaging equipment offers the quality, security and comfort desired by both the manufacturer and the end-user. Have a look at the best High speed wrap around case packer for website info..

What Are The Vacuum Packaging, Filling, Sealing, Freezing, Cooling, Labeling, And Box Forming Machines Work?

Vacuum packaging equipment is a device which remove air from the bags surrounding products and seal them. This extends the product's shelf-life. They use an air vacuum unit and a the heat sealer to seal containers or bags that contain a product. They can be programmed to disperse a certain amount of product. They are usually employed for pastes, liquids or powders.

Sealing machines. These machines use heat, pressure and heat to seal packages or bags made from plastic or other products that can be sealed with heat. They can be used to seal products like medical supplies, food items, or electronics.

Labeling machines apply labels to the products as well as packages. They can apply labels that are heat-sensitive, pressure-sensitive, or pressure-sensitive or glue to secure the label to the product.

Box-forming machines- They create boxes and cartons out of flat sheets made from paperboard. They glue and fold the paperboard in the desired shapes and then prepare it to be packed or shipped.

The machines and equipment utilize different technology to perform their jobs, which includes sensors control, a variety of mechanical systems. For added speed and efficiency, they can be integrated into larger packaging lines. Take a look at the best wrap around case packing yogurt for more examples..

Automated, scalable cooling solutions provide effective, automated temperature control for a range of industrial processes. They typically employ advanced technology, including refrigeration units, heat exchangers and temperature control systems to offer precise temperature control and guarantee the safety and quality of the products being produced. Automated and scalable cooling solutions can be tailored to meet specific customer needs. They can be easily adjusted to scale up or down when production demands change. They are also able to be integrated with other manufacturing systems to increase efficiency and boost overall production processes. Automated cooling solutions that are scalable offer numerous benefits, including increased quality of products and less time to repair. Take a look at the most popular Enoline for site examples..

What Are The Top Factors To Consider When Buying Packaging Equipment?

Specific requirements for the product- The packaging equipment used will be determined based on the volume of production that is desired.

Integration- Consideration is required to consider how the packaging equipment can integrate with the existing manufacturing lines, which includes compatibility with other equipment as well as the ease of integration.

Maintenance and Support It's crucial to assess the quality of maintenance and support services as well as the cost of equipment as well as the ease of maintenance.

Cost- Include the cost of equipment, as well as related costs such as installation, training maintenance, repairs, and so on in your overall budget.

Energy efficiency- Efficiency of energy and the associated costs should be taken into consideration, since energy consumption has an enormous impact on operating expenses.

User-friendly- With user-friendly controls and functions, the device will be simple to maintain and operate.

Conformity with industry standards- It is important to be aware of the applicable standards in the industry, for example regulations on food safety to ensure that the equipment you choose to use is suitable for the purpose it was designed to serve.

These elements enable you to make an educated choice of equipment for packaging. This will ensure that the equipment you purchase meets the requirements of your business and delivers the best performance and effectiveness. See the top Energetic group of creative, powerful, and fun professionals for more info..

What Should You Be Aware Of Regarding Heat Sealing And Product Safety

Heat sealing is a process used for packaging that seals bags or packages made from material that can be heat sealed, like plastic. The process makes use of heat and pressure to bond the materials together, creating a tight, durable seal.Product security- Heat sealing is an important factor in ensuring product safety, as it prevents contamination and keeps products fresh.

Seals that can be trusted Good seal on the heat is crucial for ensuring reliability. Inadequate sealing could cause product loss, spoilage, or leaks.

Automated packaging methods- Heat sealing is frequently done using machines for packaging that are automated. This increases efficiency and consistency.

Robotics/programmable Logical Controllers- Robotics/programmable controllers are commonly used in automated packaging processes.

A preventive maintenance program for packaging machinery- Proper maintenance of packaging equipment, heat sealing equipment and other equipment is essential for ensuring reliability and prolonging the lifespan of the equipment.

In order to maximize the efficiency of packaging materials, film usage The kind and quantity of heat seals used have a significant effect on the packaging's cost-efficiency. The best film can reduce waste, increase production speed and improve product quality.

Lower cost of packaging It is crucial to optimize the packaging process which includes heat sealing to cut down on wasted packaging and improve efficiency.

The process of packaging is called heat sealing. It is just one part of the overall packaging process that includes several other steps, like labeling, filling, and boxing. It is vital to know the entire process and how heat sealing fits into it, in order to have a profitable and cost-efficient packaging operation. Have a look at the top rated Digital printing technology for blog recommendations..